Application Fields

Engineering plastics

In filling and/or reinforcing materials PA, PBT, PET, PC and alloy continuous feeding of long or short glass fiber (including special requirements of natural glass fiber), high torque and high speed CX/RXT series extruders, with the highest productivity per unit volume.

adhesive

The TSE, RXT and CX series extruders are configured to continuously produce cement, pressure-sensitive and reactive RTV sealants with L/D >> 60 and offer a variety of downstream feed options to accommodate a wide range of liquid and solid components. The specific machine family for each application depends on the final adhesive viscosity (relative to energy consumption requirements).

Direct extrusion

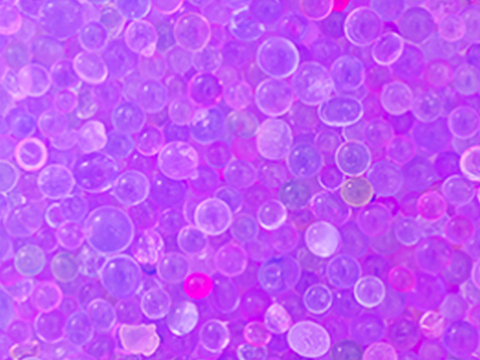

CPM Extrusion Group has developed a systemwide capability to directly extrude sheet/film/fibre, integrating upstream twin-screw extruders and associated feed equipment with melt pumps and downstream reel processing. For example, TSE, RXT, and CX extruders can produce PE fibers (high molecular weight polyethylene), microporous membranes for battery diaphragms, and PET sheets (from recycled PET).

Professional application

Industries other than plastics utilize the CPM Extrusion Group's extensive experience in custom-designed twin-screw extrusion machinery and metallurgical expertise to achieve extreme wear resistance and corrosion resistance. These extruders are used in the production of ceramic catalyst carriers, biomass fractionation and other processes in the fine chemical industry.

Food (humans and pets)

CPM Extrusion Group equipment delivered to the food and feed industry is producing direct puffed cereals and snacks, non-puffed pet snacks, aquaculture feed and confectionery products. These extruders use sanitary design and construction materials suitable for GMP environment as required.

Powder coatings and toners

CPM extruders are widely accepted in the powder coating industry for their mature split barrel design and the extremely high wear resistance of screw and barrel bushings. CX series extruders adopt specially designed screw element design, which can feed high capacity, excellent dispersion of high percentage of fine powder.

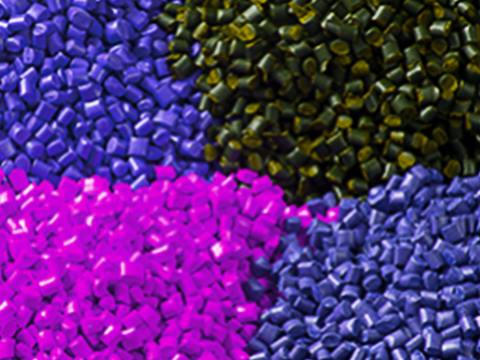

master batch

All CPM Excretion Group twin-screw extrusion systems for masterbatch and additive masterbatch are designed for pre-mixing or batch feeding (using a side feeder downstream) with a quick change feature to facilitate quick change. Extruders developed for high fill of CaCO3 masterbatch (>75% fill volume) have been delivered with a variety of granulation systems including subsea and water ring.

Reactive extrusion

Our CX, RXT and TSE series extruders are used in the production of TPU and TPV, MAH grafting and peroxide crosslinking processes. Multiple machines are combined (for example, one extruder is fed directly into a second extruder) to extend residence time and have multiple vacuum devolatilization stages to remove solvents or reaction by-products.

PVC, XLPE and cable applications

TSC Series Double Stage Extrusion Systems are designed for use in PVC (plasticized and rigid), XLPE, HFFR and other heat/shear sensitive materials. These systems tightly couple TSE or RXT series twin-screw extruders to single-screw extruders for granulation or direct extrusion of sheet/profiles. Large diameter single screw extruders operate at low speeds to minimize melting temperatures.